Top 5 Best Dairy Barn Equipment for Optimal Milk Production?

In the competitive world of dairy farming, choosing the right dairy barn equipment is crucial for success. Expert John Smith, a leading authority in dairy farming, emphasizes, "Quality dairy barn equipment can significantly enhance milk production and cow comfort." This highlights the importance of investing in the right tools.

Modern dairy barn equipment includes milking machines, feeding systems, and ventilation setups. Each piece plays a vital role in the dairy's overall efficiency. Well-designed equipment not only increases productivity but also improves the well-being of the cows. However, purchasing the best equipment often requires careful consideration and significant investment.

Farmers face many challenges. The wrong choice can lead to waste and reduced output. Therefore, understanding what equipment works best for individual farms is essential. The top five dairy barn equipment selections are not just about technology; they reflect a commitment to optimizing milk production while ensuring animal welfare. These choices require ongoing evaluation and adjustment to meet both operational and animal needs.

Understanding the Importance of Dairy Barn Equipment for Milk Production

Dairy barn equipment plays a crucial role in milk production. Effective tools can enhance efficiency and ensure high quality. Proper milking machines, for example, streamline the milking process. They reduce stress for both cows and workers. This leads to higher milk yields and better cow health.

Additionally, maintaining the right temperature in storage tanks is vital. If temperatures fluctuate, milk quality suffers. Unsuitable storage can lead to spoilage and wastage. Regular maintenance of refrigeration systems can prevent these issues. Barn layout also matters. An organized space can facilitate smoother workflow. However, overcrowding may create complications.

Investing in technology can improve overall productivity. Smart monitoring systems can track cows' health. This helps in early diagnosis of issues. Yet, relying too heavily on technology can neglect hands-on care. Finding balance is key. Equipment should complement, not replace, human interaction.

Key Features of Effective Milking Systems in Dairy Barns

Choosing effective milking systems is crucial for dairy barns. Efficiency affects overall milk production. Modern systems offer automation, which can save time. They often include milk meters. These meters help monitor yield and quality. Ensuring proper sanitation is vital. Clean equipment means better milk quality.

Remember, the layout of your milking parlor matters. It should allow smooth movement for both cows and workers. Crowded spaces can lead to stress. Stress impacts milk yield. Always prioritize animal comfort.

**Tip**: Regularly check equipment for wear. Faulty parts can disrupt milking. Identify issues before they become major problems.

Another key feature is the ability to customize settings. Each herd is unique. What works for one barn may not work for another. Flexibility ensures that the system meets specific needs. It's essential to analyze performance regularly. Reflect on what works and what doesn’t. Continuous improvement should be the goal.

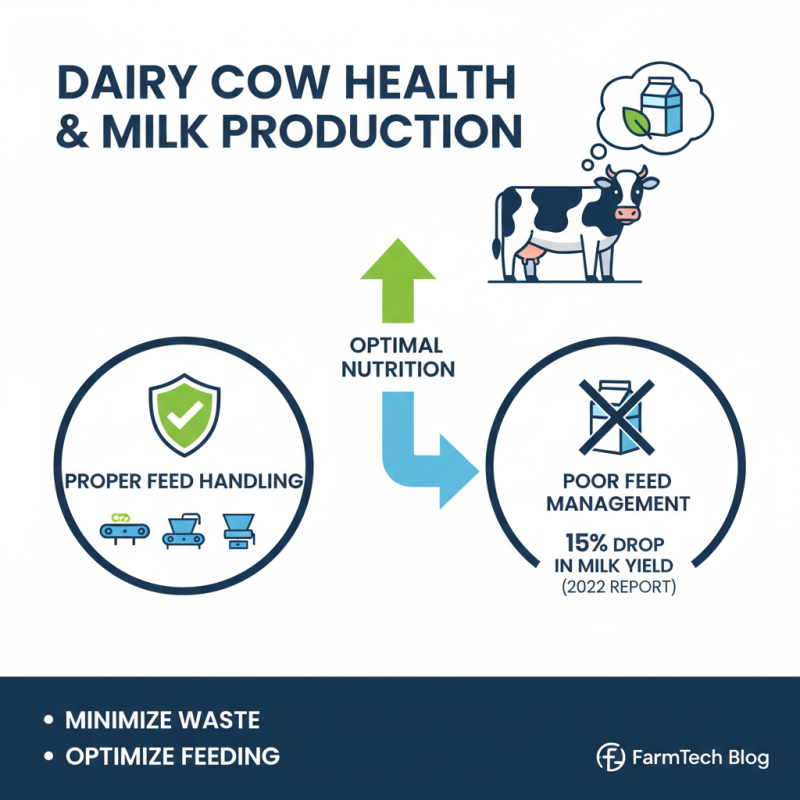

Essential Feed Handling Equipment for Dairy Cows’ Health

In dairy farming, the health of cows is paramount for milk production. Proper feed handling equipment plays a crucial role in ensuring that cows receive the right nutrition. According to a 2022 industry report, poor feed management can lead to a 15% drop in milk yield. This highlights the need for effective equipment to minimize waste and optimize feeding routines.

One essential tool is the automated feed mixer. It ensures consistent feed quality and prevents ingredient segregation. Proper mixing can enhance digestibility, which is vital for maintaining cow health. Regular checks on the feed quality can prevent issues that may arise from poor mixing. Aim to keep a daily log of feed adjustments and monitor cow responses to changes.

**Tip:** Invest in sensors that monitor feed intake. They can provide insights into individual cow health and alert you to potential issues.

Another critical piece is the feed bunk management system. This ensures that cows have access to fresh feed throughout the day. Access to quality feed encourages cows to eat more, promoting better milk production. However, if not managed correctly, feed bunks can become contaminated or overflow, which can lead to waste.

**Tip:** Consider implementing a schedule for cleaning feed bunks. Keeping them clean will help prevent disease and improve cow comfort.

Reflecting on these aspects can allow farmers to recognize areas needing improvement. Just remember, a healthy cow is vital for a productive dairy operation.

Climate Control Solutions for Enhanced Dairy Barn Environments

Climate control in dairy barns is crucial for optimal milk production. A well-regulated environment ensures cow comfort, which directly influences milk yield. According to recent studies, cows in optimal temperature zones can produce up to 20% more milk. High humidity and heat stress can hinder their performance significantly.

Ventilation systems play a major role in maintaining a balanced climate. Effective airflow reduces heat buildup and enhances air quality. Farmers report that barn temperatures exceeding 75°F (24°C) can lead to a 10% decline in milk output. Coupled with humidity control, these systems mitigate stressors that disrupt a cow's well-being.

However, many dairy farmers struggle with implementing these solutions. Initial costs can be daunting. Maintenance challenges also arise, especially in older barns. Without proper oversight, systems can fail, leading to adverse conditions. The message here is clear: investing in climate control is not just wise; it’s essential for sustaining productivity. Balancing costs against potential gains is a continual challenge in the dairy industry.

Top 5 Best Dairy Barn Equipment for Optimal Milk Production

| Equipment Type | Key Features | Benefits | Estimated Cost ($) |

|---|---|---|---|

| Automatic Milking System | Robotic milking, 24/7 operation | Increased milk yield, labor savings | $150,000 |

| Environmental Control System | Temperature and humidity monitoring | Optimal cow comfort, improved milk quality | $20,000 |

| Manure Management System | Automated scraping and handling | Reduced labor, better hygiene | $30,000 |

| Feed Dispenser | Automated feed delivery | Consistent feeding, minimized waste | $10,000 |

| Watering System | Automated filration and delivery | Improved hydration, health benefits | $15,000 |

Maintenance Practices to Ensure Longevity of Dairy Equipment

Proper maintenance of dairy barn equipment is crucial for optimal milk production. Regular checks can prevent small issues from turning into costly repairs. Inspect milking machines often for wear and tear. Broken parts can disrupt operations and affect milk quality. A worn-out vacuum pump can lead to poor suction. This affects the efficiency of milk extraction.

Cleaning is another vital practice. Daily scrubbing of surfaces prevents bacterial growth. Milk residue can lead to hygiene issues. Check for leaks in pipelines; these can waste water and create mold. Pay attention to temperature control in storage areas. If it's too warm, milk quality declines.

It’s important to train staff in maintenance protocols. They should understand the significance of quick repairs. However, even the best-trained personnel may overlook details. Setting a routine helps, but complacency can set in. Equipment may be neglected over time. Regular audits can ensure everything is in top shape.

Related Posts

-

Top 10 Essential Milking Parlour Equipment for Optimal Dairy Farm Efficiency

-

Essential Guide to Choosing Innovative Dairy Milking Equipment for Modern Farms

-

Essential Dairy Barn Equipment Upgrades for Modern Farming Efficiency

-

The Future of Dairy Farming How Cow Milking Equipment is Revolutionizing Milk Production

-

2025 Top Milking Equipment Innovations for Modern Dairy Farming

-

2025 How to Choose the Best Dairy Milking Equipment for Your Farm