Top 10 Best Dairy Industry Equipment for Efficient Production Systems?

The dairy industry is evolving rapidly. Efficient production systems rely heavily on state-of-the-art dairy industry equipment. According to Dr. Emily Roberts, an expert in dairy technology, "Investing in modern equipment is crucial for sustainable milk production."

In a competitive market, utilizing the best dairy industry equipment can significantly enhance productivity. Tools like automated milking systems and advanced cooling technologies improve efficiency. Yet, some farm owners hesitate to upgrade their equipment due to high costs. This cautious approach can hinder growth and future profitability.

While new equipment can be an investment, it often pays off in the long run. The right technology not only streamlines processes but also ensures quality. However, there is a temptation to settle for outdated systems due to comfort. Striking a balance between tradition and innovation is key.

Overview of Dairy Industry Equipment and Their Importance

In the dairy industry, efficient production systems rely heavily on advanced equipment. Various tools enhance productivity, improve hygiene, and ensure product quality. For example, pasteurizers play a crucial role in killing harmful bacteria. They help maintain the safety of milk products. Furthermore, automated milking systems reduce labor costs and increase milking efficiency. Dairy farmers benefit greatly from these innovations.

Tips: Regular maintenance is essential for all dairy equipment. Neglect can lead to costly breakdowns. Don't overlook small issues; they can snowball into bigger problems.

Choosing the right equipment is vital. Each piece serves a unique function. Chillers keep milk fresh and at the correct temperature. However, sometimes these systems fail silently. It’s important to monitor performance closely and make adjustments as needed. Relying solely on technology without regular checks can backfire.

Investing in quality equipment pays off. You ensure better yield and less waste. Remember, training staff on proper use is just as important. Untrained personnel might misuse advanced tools, leading to inefficiencies. Balancing technology with human oversight is key.

Key Factors for Selecting Dairy Production Equipment

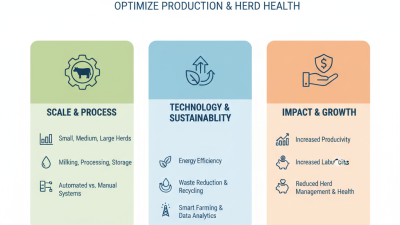

Selecting the right dairy production equipment can significantly enhance efficiency and productivity. When evaluating options, it's essential to consider a few key factors. First, assess the scalability of the equipment. Your production needs might grow, so choosing adaptable machines is critical. Look for equipment that can handle varying volumes without substantial upgrades.

Another vital consideration is energy efficiency. Equipment that consumes less energy can save costs in the long run. Analyzing the energy consumption of machinery can reveal surprising insights. Remember, high performance often does not equate to high energy use.

Tips: Always check the maintenance requirements. Some machines have complex maintenance needs that can disrupt operations. Regular upkeeping should be manageable for your team.

Also, prioritize equipment that promotes hygiene and safety. Clean machinery reduces contamination risks, which is non-negotiable in dairy production. Equipment that’s easier to clean can lead to better compliance with health standards.

In conclusion, true efficiency comes from not just choosing advanced equipment, but also understanding its practical implications and maintenance demands. Balancing technology with day-to-day operations is key to a successful dairy production system.

Top Dairy Processing Machines for Maximum Efficiency

In the dairy industry, efficiency relies heavily on the right equipment. Selecting the best machinery can significantly enhance production. Dairy processing machines streamline operations, reduce waste, and boost productivity.

Consider investing in pasteurizers. These machines ensure safety and quality. They heat milk to eliminate harmful bacteria. A reliable pasteurizer can make or break your production line. Think about the cleaning process too. Hygiene is paramount in dairy.

Automated cleaning systems save time and labor.

Don't overlook the importance of cooling systems. Proper cooling maintains milk freshness. Inefficient cooling can spoil products quickly. Regular maintenance of cooling units is essential. It might seem simple, but neglecting this can lead to large losses.

Tip: Always calibrate your equipment regularly. Small adjustments can greatly improve efficiency. Additionally, train staff on best practices. This knowledge can help prevent costly mistakes. Investing in training pays off in long-term productivity.

Innovative Technologies in Dairy Production Equipment

The dairy industry is rapidly evolving. Innovative technologies are transforming dairy production equipment. These advancements help increase efficiency. For instance, automated milking systems reduce labor costs. They also improve animal welfare by allowing cows to be milked on their own schedule. This fosters a calmer environment for the cows.

Another significant technology is smart sensors. They monitor milk quality in real time. These sensors detect changes in temperature and composition. If something is off, the system alerts the operator immediately. This proactive approach ensures only high-quality milk reaches the consumer.

However, not all innovations are perfect. Some technologies can be costly to implement. Smaller farms may struggle to afford them. There’s a fine balance between embracing new tools and managing budget constraints. Efficiency should not come at the cost of financial stability. Each farm must assess their unique needs carefully.

Top 10 Best Dairy Industry Equipment for Efficient Production Systems

| Equipment Type | Function | Key Features | Efficiency Gain | Estimated Cost (USD) |

|---|---|---|---|---|

| Milk Pasteurizer | Heat treatment of milk | Auto temperature control, compact design | 30% reduction in heating time | $25,000 |

| Automatic Milking Machine | Automated milking process | Robotic arms, real-time monitoring | 40% labor savings | $75,000 |

| Milk Separation Equipment | Separating cream from milk | High speed, low energy consumption | 20% more cream yield | $18,000 |

| Cooling Tank | Cooling and storage of milk | Insulated, multi-stage cooling | 15% lower energy costs | $10,000 |

| Dairy Feed Mixer | Mixing feed ingredients for cows | Batch control, adjustable settings | 25% faster mixing | $7,500 |

| Cloning Machine | Breeding and genetics improvement | Genome analysis, high success rate | Improving herd quality by 30% | $150,000 |

| Cream Whipping Machine | Whipping cream for retail | Continuous system, adjustable speed | 10% more whipped cream produced | $9,000 |

| Packaging System | Packaging dairy products | Automation, precision sealing | 35% faster packaging | $20,000 |

| Quality Control Systems | Monitoring milk quality | Sensors, real-time data analysis | Reducing spoilage by 50% | $12,000 |

Maintenance and Safety Considerations for Dairy Equipment

Maintenance and safety are crucial in dairy production systems. Proper upkeep of equipment enhances efficiency and product quality. Regular inspections can prevent unexpected breakdowns. Training staff on equipment use is essential. Well-informed employees can spot issues early.

Consider the importance of cleaning protocols. Dairy equipment must be sanitized to ensure product safety. Neglecting this increases contamination risks. Implementing a cleaning schedule helps maintain hygiene standards. Inspecting seals and connections regularly protects against leaks. Leaks can lead to serious safety hazards.

Emergency response plans should be in place. Equipment failures can occur at any moment. Staff must know how to react quickly. Fire extinguishers and first aid kits should be accessible. Conduct regular safety drills to ensure everyone is prepared. Reflecting on past incidents can help improve future safety measures.

Top 10 Best Dairy Industry Equipment for Efficient Production Systems

Related Posts

-

2025 How to Choose the Best Dairy Milking Equipment for Your Farm

-

How to Choose the Best Dairy Equipment for Your Farm in 2025

-

2025 How to Choose the Best Dairy Equipment for Your Farm Production

-

How to Choose the Right Dairy Production Equipment for Your Farm Needs

-

Top 10 Essential Milking Parlour Equipment for Optimal Dairy Farm Efficiency

-

Top Tips for Choosing the Best Milking Equipment for Your Dairy Farm