Why Choose Stainless Steel Woven Wire Mesh for Your Projects?

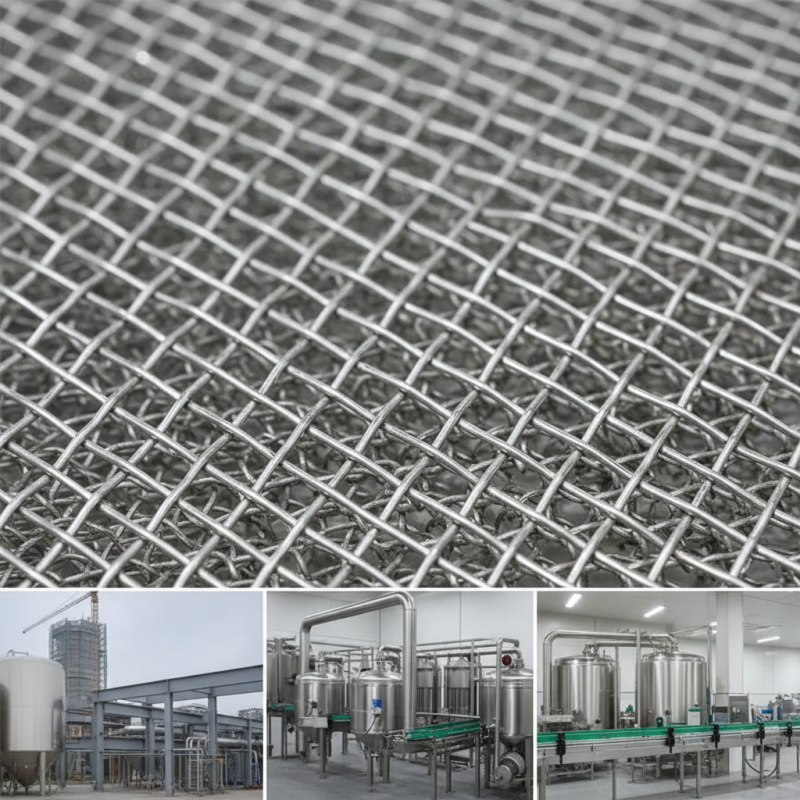

stainless steel woven wire mesh is increasingly popular in various industries. This versatile material offers strength, durability, and resistance to corrosion. According to a 2022 industry report by Market Research Future, the global demand for stainless steel woven wire mesh has grown by 15% annually. This growth reflects its wide application in construction, filtration, and food processing sectors.

Expert Anna Mendez, a leading authority on industrial materials, noted, "stainless steel woven wire mesh is unmatched for its performance in tough conditions." This sentiment resonates with many manufacturers seeking reliable materials. However, challenges remain. Sourcing high-quality mesh and ensuring proper installation can complicate projects. Quality control and supplier reliability must be prioritized to avoid potential pitfalls.

In conclusion, the utility of stainless steel woven wire mesh can't be overstated. Yet, navigating the market requires diligence and knowledge. As industries evolve, this material’s prominence will likely continue to rise, shaping future engineering solutions.

Benefits of Stainless Steel Woven Wire Mesh in Various Applications

Stainless steel woven wire mesh offers numerous advantages for various projects. Its durability makes it an excellent choice for construction purposes. Unlike other materials, stainless steel doesn’t rust or corrode easily. This resistance extends its lifespan, reducing the need for frequent replacements. Mesh can be used in architectural designs, enhancing aesthetics while providing structure.

In industrial settings, steel mesh proves its versatility. It’s used in filtration systems to ensure clean processes. In food production, it maintains hygiene standards and prevents contamination. Its strength can support heavy loads, making it ideal for safety barriers. However, using the correct mesh size is crucial. Oversized openings may compromise safety or functionality.

Some projects may face issues with installation. Precise measurements are vital for fitting and usability. Misalignments can lead to inefficiency and increased costs. Thus, careful planning is essential. Stainless steel woven wire mesh provides benefits, but it requires thoughtful application to achieve the best results.

Why Choose Stainless Steel Woven Wire Mesh for Your Projects? - Benefits of Stainless Steel Woven Wire Mesh in Various Applications

| Application | Benefits | Material Properties | Common Mesh Sizes |

|---|---|---|---|

| Food Processing | Corrosion resistance, easy to clean | Non-reactive, strong | 2mm, 4mm, 6mm |

| Filtration | High strength, durability | Heat-resistant, stable | 50 mesh, 100 mesh |

| Construction | Longevity, aesthetic appeal | Weather-resistant, structural integrity | 10mm, 20mm, 30mm |

| Mining | High tensile strength, abrasion resistance | Reliable under stress, tough | 40 mesh, 80 mesh |

| Aviation | Lightweight, high performance | Resilient, low maintenance | Fine mesh options available |

Durability and Corrosion Resistance of Stainless Steel Woven Wire Mesh

Stainless steel woven wire mesh offers exceptional durability and corrosion resistance. Research shows that stainless steel can withstand various environmental conditions, making it ideal for both indoor and outdoor use. In fact, studies reveal that high-strength stainless steel can last over 50 years without significant degradation. This longevity makes it a preferred choice in many construction and industrial applications.

Corrosion resistance is another crucial factor. Stainless steel contains chromium, which forms a protective layer on the surface. This layer prevents rust and other forms of corrosion. According to industry analysts, the cost of replacing corroded materials can reach up to 20% of the initial investment for businesses. Using stainless steel reduces these long-term maintenance costs dramatically. It’s important to note, however, that not all stainless steel is created equal. Different grades offer varying levels of resistance, so careful selection is necessary.

However, stainless steel woven wire mesh may have some imperfections. For example, in highly acidic environments, even high-grade stainless steel can corrode. Projects in such zones might require additional protective measures. This is an area that warrants close inspection and consideration. Being aware of the limitations can guide selection and ensure project success.

Versatility of Woven Wire Mesh in Industrial and Commercial Use

Stainless steel woven wire mesh is increasingly popular in various industrial and commercial applications. Its versatility makes it suitable for numerous uses, from filtration to structural support. According to a recent industry report, the demand for woven wire mesh is expected to grow by 5% annually, reflecting its importance in manufacturing and construction.

In the food processing industry, stainless steel mesh aids in ensuring safety and hygiene. It effectively filters contaminants while being easy to clean. Many manufacturers prefer it for its rust-resistant qualities. However, one should consider the mesh's size carefully. Choosing the wrong specifications can lead to issues in filtration efficiency and product quality.

Tips: Always assess the environment where the mesh will be used. High humidity can affect durability. Also, bear in mind that while stainless steel is robust, it’s not impervious to corrosion under extreme conditions. For architectural uses, the aesthetic appeal of woven wire mesh enhances visual designs. However, balance functionality with design to avoid compromising structural integrity.

Comparison of Stainless Steel with Other Wire Mesh Materials

When comparing stainless steel woven wire mesh to other materials, its advantages stand out. According to a 2021 report from the International Wire Association, stainless steel has a tensile strength of 750 MPa on average. This makes it robust for various applications. In contrast, aluminum wire mesh usually has a tensile strength of only around 230 MPa, making it less suitable for high-stress environments.

Corrosion resistance is a crucial factor. Stainless steel mesh is highly resistant to rust and corrosion, especially in harsh conditions. A study by the National Association of Corrosion Engineers indicates that stainless steel can last over 20 years in coastal environments, while carbon steel may deteriorate within just a few years. This durability makes stainless steel more cost-effective in the long run.

However, stainless steel can have its drawbacks. It is heavier and typically more expensive than alternatives like plastic or fiberglass mesh. These factors can complicate installation and increase upfront costs. Additionally, decisions about mesh size and weave type can affect performance and cost. It's essential to weigh these variables carefully when considering materials for specific projects.

Comparison of Wire Mesh Material Performance

This chart illustrates the performance ratings of various wire mesh materials including corrosion resistance, strength, and durability. Stainless steel clearly outperforms the other materials, making it an ideal choice for various projects.

Key Considerations When Selecting Stainless Steel Woven Wire Mesh

When selecting stainless steel woven wire mesh, several key considerations come into play. One important factor is the mesh's weave pattern. A tighter weave can improve strength, while a looser pattern may enhance flexibility. Think about the specific requirements of your project. Some applications demand robustness, while others prioritize airflow.

Material thickness also plays a crucial role. Thicker wires tend to increase durability. However, they may reduce the mesh's ability to pass light or liquid. Consider the balance between strength and permeability. It can be tricky to find the right fit. A mesh that fits one requirement might not suit another.

Next, consider the corrosion resistance of your chosen material. Stainless steel offers natural resistance, yet different grades vary in effectiveness. Higher quality grades generally perform better in harsh environments. It's essential to assess the conditions where the mesh will be used. A mismatch could lead to premature failure. Reflect on these factors. They can determine the success of your project.