Top Tips for Choosing the Best Milking Equipment for Your Dairy Farm

Choosing the right milking equipment is a crucial decision for any dairy farm, impacting both efficiency and milk quality. With the dairy industry evolving rapidly, farmers need to stay informed about the latest advancements in milking technology. The variety of milking equipment available can be overwhelming, but understanding the key features and benefits can simplify the selection process. This comprehensive guide aims to provide top tips for choosing the best milking equipment that aligns with your farm's specific needs and goals.

When investing in milking equipment, factors such as herd size, milking frequency, and the overall management plan of your dairy operation must be considered. The right equipment not only enhances productivity but also ensures the health and well-being of the cows. Additionally, efficient milking systems can lead to higher milk yields and better quality produce, boosting profitability in the long run. By evaluating your farm's requirements and the latest innovations in milking technology, you can make an informed decision that caters to both your operational needs and welfare standards in dairy farming.

Factors to Consider When Selecting Milking Equipment for Dairy Farms

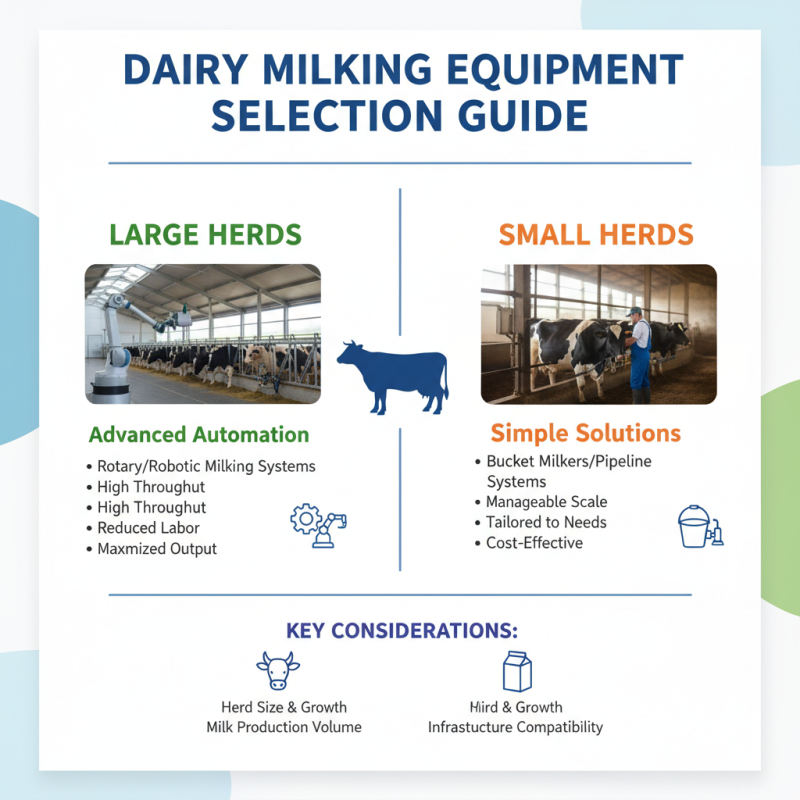

When selecting milking equipment for your dairy farm, several critical factors must be considered to ensure that your investment meets both your operational needs and animal welfare standards. First, assessing the size of your dairy operation is essential. This includes evaluating the number of cows to be milked, the available space for equipment, and the anticipated milk production levels. Larger herds may require more advanced solutions such as automated milking systems, while smaller farms may benefit from simpler, more traditional setups that are easier to manage.

Another important aspect to consider is the technology incorporated into the milking equipment. Look for features that enhance productivity and efficiency, such as automatic cluster removers, milk meters, and systems that provide real-time data on milk yield and quality. Additionally, ease of cleaning and maintenance should not be overlooked, as proper hygiene practices are vital for ensuring high milk quality. Furthermore, evaluate the equipment’s compatibility with existing systems on your farm, such as bulk tanks and cooling systems, to streamline the entire milking process. By carefully considering these factors, you can choose milking equipment that not only supports your dairy operation but also promotes the well-being of your livestock.

Understanding Different Types of Milking Systems and Their Efficiency Ratings

When choosing milking equipment for your dairy farm, it's crucial to understand the different types of milking systems available and their corresponding efficiency ratings. Milking systems can be generally categorized into three main types: traditional bucket milking, pipeline milking, and automated milking systems (AMS). A recent study by the Dairy Research Institute indicates that automated milking systems can improve milk yield by 10-15% compared to traditional methods due to their optimized milking processes and reduced stress on cattle.

Additionally, the efficiency of these systems can also be assessed through key performance indicators such as milking time, udder health, and overall milk quality. According to the American Dairy Association, modern pipeline systems, which use a network of pipes to transport milk directly from the cow to storage tanks, achieve a milking efficiency rating of 85%, while AMS can reach up to 90% due to their ability to adapt to individual cow needs and optimize milking schedules. Understanding these metrics can greatly enhance decision-making, ensuring that dairy farmers select the best milking equipment that aligns with their production goals and operational capabilities.

Evaluating Milking Equipment Based on Herd Size and Milk Production Volume

When selecting milking equipment for your dairy farm, it's essential to consider both herd size and milk production volume. Larger herds typically require more advanced automation systems that can efficiently manage the milking process while maximizing output and minimizing labor. In contrast, smaller operations may opt for simpler, more manageable solutions tailored to their specific needs. Assessing the capacity of milking machines and their compatibility with your existing infrastructure can greatly enhance productivity.

**Tip:** Evaluate your herd's milking routine to determine the right equipment. For herds with frequent milking schedules, investing in high-capacity machines designed for rapid throughput may be beneficial. However, if you have a smaller, less demanding herd, consider equipment that balances efficiency with ease of use, ensuring that your milking process remains smooth without overextending your budget.

Additionally, calculating your expected milk production volume helps in choosing the appropriate equipment. It is crucial to select milking machines that can handle peak production periods without compromising the quality of milk. Monitoring variables such as milk yield per cow and frequency of milking can provide insights into the most suitable equipment configurations for your operation.

**Tip:** Regularly review your production data to adjust your equipment choices as your herd grows or milk yield fluctuates. This proactive approach will ensure that your milking equipment stays aligned with your farm's evolving needs, leading to better efficiency and profitability in the long run.

The Importance of Regular Maintenance and Upgrades for Milking Machinery

Regular maintenance and timely upgrades of milking machinery are crucial for optimizing the efficiency and productivity of your dairy farm. Routine checks not only enhance the longevity of the equipment but also ensure that milking processes run smoothly without interruptions. Regular maintenance tasks, such as cleaning the milking lines, checking for wear and tear, and inspecting vacuum systems, can prevent costly breakdowns and minimize downtime. By maintaining a stringent maintenance schedule, dairy farmers can promptly identify and resolve potential issues before they escalate into more significant problems.

Additionally, staying up-to-date with technological advancements in milking equipment can lead to significant improvements in milk quality and overall farm profitability. Upgrading machinery not only incorporates efficiency-enhancing features but also aligns with current industry standards, ensuring compliance with health and safety regulations. Investing in modern technology can also optimize milking times, reduce labor costs, and enhance the overall comfort of both the dairy animals and the workers. By prioritizing regular maintenance and considering necessary upgrades, dairy farmers can position themselves for long-term success in an increasingly competitive market.

Cost Analysis: Initial Investment vs. Long-term Savings in Milking Equipment

When selecting milking equipment for your dairy farm, it’s essential to conduct a thorough cost analysis that weighs both the initial investment and the potential long-term savings. The upfront cost of purchasing milking systems can vary significantly based on technology, capacity, and features. Higher-end systems often come with advanced automation and efficiency that could seem expensive at first glance. However, it's crucial to consider how these investments can enhance productivity, reduce labor costs, and minimize waste, ultimately affecting your bottom line.

Long-term savings can manifest in several ways. Automated milking systems may reduce the time spent on daily operations, allowing for better herd management and increased milk yield. Additionally, more efficient equipment can lead to lower energy and maintenance costs over the years. Regularly investing in new, innovative technologies may seem daunting at the outset, but the return on investment can be significant, making your dairy farm more sustainable and profitable in the long haul. Therefore, weighing these factors will help you make a more informed decision that aligns with both your immediate budget and your long-term financial goals.

Top Tips for Choosing the Best Milking Equipment for Your Dairy Farm - Cost Analysis: Initial Investment vs. Long-term Savings in Milking Equipment

| Equipment Type | Initial Investment ($) | Annual Operating Cost ($) | Estimated Lifespan (Years) | Long-term Savings ($) | Efficiency Rating (1-10) |

|---|---|---|---|---|---|

| Rotary Milking Parlor | 150,000 | 20,000 | 15 | 100,000 | 9 |

| Parallel Milking System | 100,000 | 15,000 | 12 | 70,000 | 8 |

| Herringbone Milking Parlor | 80,000 | 12,000 | 10 | 50,000 | 7 |

| Swing-Over Milking System | 90,000 | 10,000 | 8 | 30,000 | 6 |

Related Posts

-

2025 How to Choose the Best Dairy Milking Equipment for Your Farm

-

Top 10 Must Try Dairy Milk Products for a Creamy Delicious Experience

-

The Surprising Health Benefits of Incorporating Dairy Products into Your Daily Diet

-

10 Essential Tips for Choosing the Best Dairy Milk Products for You

-

Top 10 Essential Milking Parlour Equipment for Optimal Dairy Farm Efficiency

-

Top 10 Health Benefits of Milk Products in Dairy Nutrition