Top Tips for Choosing Milking Equipment Manufacturers for Your Dairy Farm

Choosing the right milking equipment manufacturers is a crucial decision for dairy farmers aiming to optimize their operations and enhance productivity. According to Dr. Jane Hargrove, a renowned expert in dairy technology, "Selecting the right milking equipment can significantly impact both the efficiency of your farm and the welfare of your animals." This underscores the importance of careful consideration when evaluating potential manufacturers, as the quality and reliability of equipment can directly influence both milk production and the overall health of the herd.

When it comes to milking equipment manufacturers, a myriad of factors must be assessed. Farmers should prioritize manufacturers that offer innovative solutions tailored to the specific needs of their dairy operations. Additionally, evaluating the support and services offered post-purchase is essential, as ongoing maintenance and technical assistance can affect the long-term performance of the equipment. As the dairy industry continues to evolve, investing in advanced milking technology becomes increasingly critical for those looking to stay competitive and sustainable.

Ultimately, choosing the right milking equipment manufacturer can lead to significant advancements in efficiency and productivity on the farm. With expert insights and a well-researched approach, dairy farmers can make informed decisions that not only benefit their operations but also contribute to improved animal welfare and milk quality.

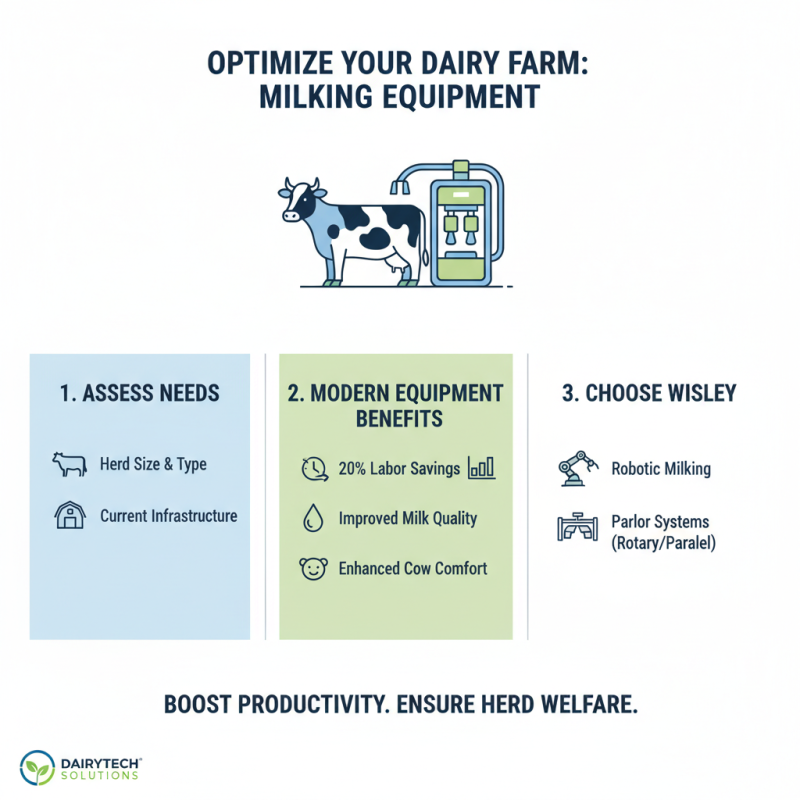

Understanding Your Dairy Farm's Milking Equipment Needs

Understanding your dairy farm's milking equipment needs is crucial for optimizing productivity and ensuring the welfare of your herd. Recent reports indicate that milking efficiency can be significantly enhanced with the right equipment, with the Association of Equipment Manufacturers noting that modern milking systems can reduce labor costs by up to 20% while improving milk quality. This data emphasizes the importance of evaluating your specific needs before investing in equipment.

When considering milking equipment, it is essential to assess factors such as herd size, milk production goals, and the layout of your dairy farm. A comprehensive needs assessment will help you determine whether to opt for traditional methods or automated systems, which can offer increased efficiency and precision. According to the International Dairy Federation, automation technologies in milking can lead to a 15-30% increase in milk yield per cow, showcasing the potential return on investment for dairies that adapt to these advancements. By understanding these aspects, dairy farmers can make informed decisions, ensuring the selected equipment aligns perfectly with their operational goals and contributes to a sustainable, profitable farming practice.

Key Features to Look for in Milking Equipment

When selecting milking equipment for your dairy farm, it’s crucial to focus on several key features that can significantly impact productivity and efficiency. One of the most important aspects is the ease of use and ergonomics of the equipment. Research indicates that user-friendly systems can reduce the labor burden and minimize the risk of injury. For instance, systems designed with adjustable heights and intuitive controls can decrease the time spent on milking and improve overall workflow efficiency by up to 20%.

Another vital feature to consider is the technology integrated into the milking equipment. Advanced systems employing automation and data collection capabilities can enhance herd management significantly. According to a report from the National Dairy Farmers Association, farms using automated milking systems reported an average increase of 15% in milk yield due to better monitoring of cow health and milking conditions. Furthermore, these systems often provide real-time data analytics, which can help farmers make informed decisions about feed management and animal care, ultimately leading to improved dairy production.

Lastly, durability and ease of maintenance are crucial considerations. Milking equipment should withstand the rigorous demands of daily use while also being easy to service. A study published in the Journal of Dairy Science noted that equipment with longer lifespan and lower maintenance needs can lead to substantial cost savings over time. Farmers should opt for materials that are resistant to wear and tear in order to ensure longevity and consistency in operation. These features combined can enhance not only the efficiency of milking operations but also contribute to the overall health and productivity of the dairy herd.

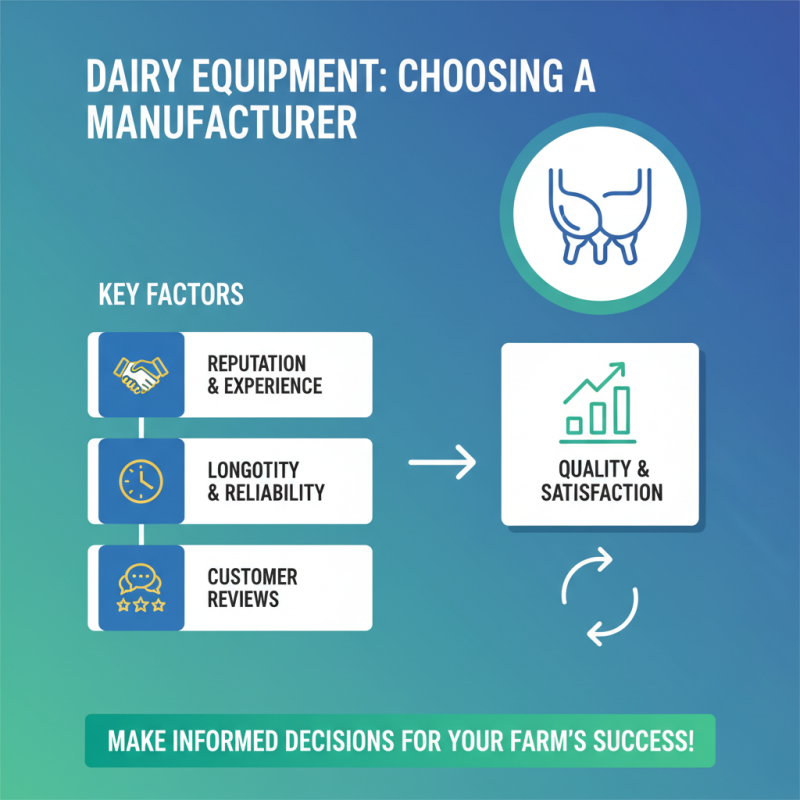

Evaluating Manufacturers: Reputation and Experience

When evaluating milking equipment manufacturers for your dairy farm, one of the most critical factors to consider is their reputation and experience in the industry. A manufacturer with a solid reputation is often a reflection of their commitment to quality and customer satisfaction. Look for companies that have been in the business for several years, as longevity often signifies reliability and expertise. Reading customer reviews and testimonials can provide insights into the manufacturer’s performance, allowing you to gauge their standing in the market.

Tip: Engage with fellow dairy farmers and industry professionals to gather recommendations on reputable manufacturers. Personal experiences can guide you toward making informed choices, leading to more successful partnerships.

Additionally, consider the manufacturer’s experience in the specific type of milking equipment you require. Different dairy operations have varying needs, so it’s essential to ensure that the manufacturer has a track record of providing equipment suited to your farm’s scale and milking process. Inquire about their technological advancements and how they stay updated with industry changes, as this can significantly impact the efficiency and productivity of your operation.

Tip: During your evaluation, ask about the manufacturer’s support and service offerings. A partnership that includes reliable after-sales service guarantees you won’t face unresolved issues further down the line, enhancing the overall dependability of your chosen equipment.

Assessing Cost vs. Quality in Milking Equipment

When evaluating milking equipment for your dairy farm, understanding the balance between cost and quality is essential. Initially, it may seem tempting to opt for lower-priced equipment to minimize upfront expenses. However, it's crucial to consider the long-term implications of these choices. Lower-cost milking systems may compromise on durability, efficiency, and features essential for maximizing milk production and maintaining herd health. Investing in high-quality equipment can lead to significant savings in repairs and replacements down the line, not to mention improved milk yield and better animal welfare.

Quality assurance should also extend to the manufacturer’s support and service options. Low-cost options might not provide adequate customer service or warranties, leaving farmers vulnerable in case of equipment failure. When selecting a milking equipment manufacturer, assess their reputation for quality and service. Engaging with current users and industry experts can provide insights into the reliability and performance of different systems. Ultimately, while the initial cost is important, weighing this against the equipment's lifespan, efficiency, and support can lead to a more profitable and sustainable dairy operation in the long run.

Importance of After-Sales Support and Service in Choosing a Manufacturer

When selecting milking equipment manufacturers for your dairy farm, after-sales support and service should be a primary consideration. The complexities involved in dairy operations mean that having reliable support is crucial for maintaining optimal productivity. A manufacturer that prioritizes after-sales service can assist with equipment installation, troubleshooting, and ongoing maintenance. This support helps to minimize downtime, ensuring your farm runs smoothly and efficiently.

Moreover, a strong after-sales service fosters a long-term relationship between the manufacturer and the dairy farm. Manufacturers that offer training sessions for your staff can significantly enhance their efficiency and competency in operating the equipment. Effective after-sales support not only addresses immediate technical issues but also provides valuable insights for future upgrades or expansions, which can be vital for the growth of your dairy operation.

Therefore, when evaluating manufacturers, pay close attention to their service offerings, as this can greatly influence your farm’s overall success and profitability.

Related Posts

-

2025 How to Choose the Best Dairy Milking Equipment for Your Farm

-

Top Tips for Choosing the Best Milking Equipment for Your Dairy Farm

-

Best Milk Producing Products You Need to Know for Higher Yields

-

Discover the Best Dairy Products Online for a Healthier Lifestyle

-

Why Buy Dairy Products Online? The Benefits You Can't Ignore

-

Top 10 Health Benefits of Milk Products in Dairy Nutrition