How to Choose the Right Milking Parlour Equipment for Your Dairy Farm?

Choosing the right milking parlour equipment is crucial for any dairy farm. The selection process can be overwhelming. With numerous options on the market, making the best choice requires careful consideration.

Farmers should assess their specific needs and herd size before purchasing. Efficiency is key. Investing in well-designed milking parlour equipment can improve productivity. It can also enhance the welfare of the cows. However, not all equipment fits every farm layout. Some may find certain machinery cumbersome or complex, leading to operational challenges.

Cost is another factor that cannot be ignored. While high-quality equipment may come with a higher price tag, it is often worth the investment in the long run. Farmers must weigh immediate costs against potential returns. Reflecting on past choices could provide insights into future purchases. Making the right decision now can save time and resources later.

Factors to Consider When Selecting Milking Parlour Equipment

When selecting milking parlour equipment, there are several critical factors to consider. First, the type of milking system should align with your herd size and milk production goals. Automatic milking systems, for instance, can enhance efficiency by allowing cows to be milked at their convenience. Research indicates that these systems can increase milk yield by up to 10% due to reduced stress and improved comfort for the animals.

The layout of the parlour also plays a vital role. A well-designed milking parlour can minimize the time cows spend waiting. It directly affects the overall productivity of your operation. Experts recommend a flow design that minimizes movement and maximizes efficiency. Considerations such as the number of milking stations and the workflow of staff must be part of the design process.

Finally, the technology integrated into your milking system is crucial. Sensors and data analytics can monitor milk quality and cow health. This technology aids in identifying problems early, allowing for timely interventions. However, investing in advanced technology can be daunting. Balancing your budget with the need for innovation requires careful thought and planning.

Types of Milking Systems: Comparing Herringbone, Parallel, and Rotary

When selecting milking systems for your dairy farm, consider three primary types: herringbone, parallel, and rotary. Each system has distinct advantages and fits different farm layouts. For example, the herringbone design allows cows to be milked in a staggered position. This setup can boost cow comfort and efficiency. According to industry data, farms using herringbone systems report a 20% increase in milking efficiency.

Parallel parlours, on the other hand, offer a straightforward approach. Cows line up next to each other, making it easier for one operator to manage multiple cows. Research indicates that parallel systems can handle a higher number of cows per hour compared to herringbone. However, the initial investment can be high, and it may require more space.

Rotary systems, popular for larger operations, provide continuous movement for milking. They save time, allowing up to 240 cows to be milked per hour. Yet, farmers should weigh the steep learning curve and maintenance costs.

Tips:

- Evaluate your current herd size and future growth.

- Maintain your equipment regularly to prevent downtimes.

- Don't rush your decision; consider your budget and workflow needs.

Choosing the right system can significantly impact your farm’s operations. Reflect on your specific requirements before committing.

Importance of Sanitization in Milking Parlour Equipment Selection

Sanitization is crucial when selecting milking parlour equipment. A clean environment protects the health of both cows and humans. Research indicates that proper cleaning can reduce bacterial counts by up to 99%. This reduction minimizes the risk of mastitis, which affects up to 25% of dairy cows. The right equipment can make a significant difference in maintaining hygiene standards.

When choosing milking parlour equipment, focus on materials that are easy to clean. Stainless steel is often the preferred choice. It resists corrosion and is non-porous, making it easier to disinfect. Ensure your equipment has smooth surfaces and minimal crevices. Bacteria can hide in hard-to-reach areas, leading to unhealthy conditions.

Tips: Implement a daily cleaning routine. Regularly inspect all equipment for wear and tear. Consider investing in automated cleaning systems. These systems can enhance efficiency and ensure thorough sanitization. Always have backup supplies of cleaning agents on hand.

The importance of sanitization cannot be overstated. Contamination can lead to costly health issues in cows. It can also affect milk quality and subsequently revenue. Finding the right balance between efficiency and cleanliness is vital. Continuous evaluation of your sanitization methods can lead to improved practices over time.

Evaluating Milking Capacity: Matching Equipment to Dairy Herd Size

When evaluating milking capacity for your dairy farm, matching equipment to herd size is crucial. The number of cows you have directly influences the type of milking parlour you need. For smaller herds, a simpler system may suffice. However, larger herds require more advanced setups. Choosing equipment that can handle your herd efficiently ensures smooth operations.

Consider the milking frequency of your cows. For instance, if cows milk three times a day, your equipment should be able to handle it without delays. Think about investment costs too. More sophisticated systems might seem appealing but could overextend your budget if not justified by your herd size. Additionally, ask yourself: is your current equipment meeting daily demands? If not, it may time for a change.

Space is another concern. Ensure you have enough room for your setup. Crowded areas can slow down the process. Also, review maintenance needs regularly. Equipment can wear down, leading to inefficiencies. Take a moment to reflect on whether your choice supports the health of your herd and maximizes output effectively.

How to Choose the Right Milking Parlour Equipment for Your Dairy Farm?

| Herd Size (Cows) | Recommended Milking Parlour Type | Milking Capacity (Cows per Hour) | Typical Setup Cost (USD) | Land Requirement (Acres) |

|---|---|---|---|---|

| Up to 50 | Parallel Milking Parlour | 20 - 30 | $50,000 - $70,000 | 1 - 2 |

| 51 - 100 | Herringbone Milking Parlour | 30 - 60 | $80,000 - $120,000 | 2 - 3 |

| 101 - 200 | Rotary Milking Parlour | 60 - 120 | $150,000 - $250,000 | 3 - 5 |

| 201 - 500 | Swing Over Milking Parlour | 120 - 200 | $250,000 - $400,000 | 5 - 10 |

| Over 500 | Automated Milking Systems | 200+ | $500,000+ | 10+ |

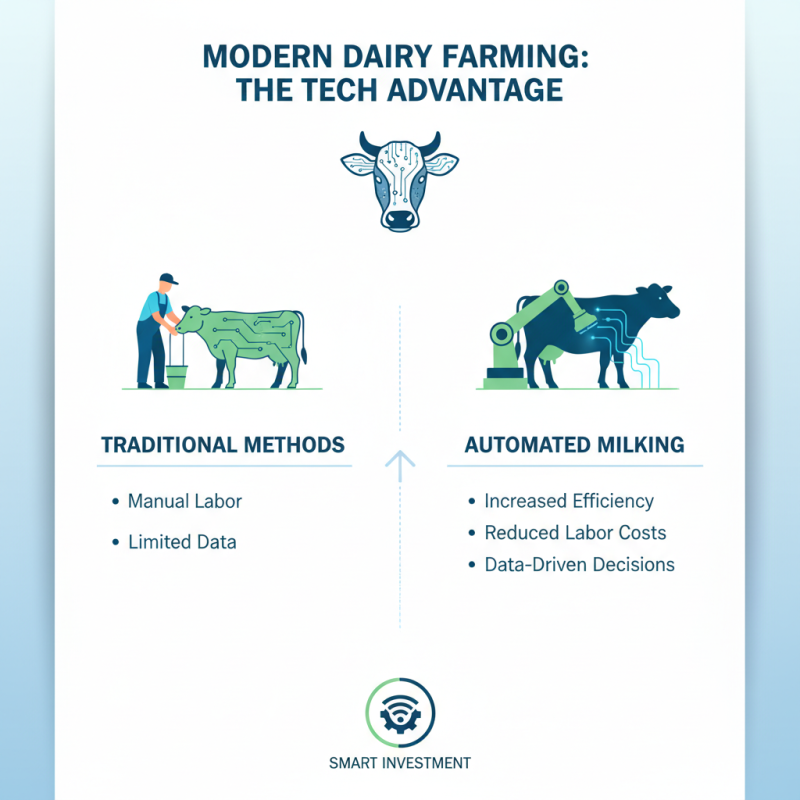

Investing inTechnology: The Role of Automation in Modern Milking Systems

Investing in technology is crucial for modern dairy farms. Automation in milking systems offers several advantages. It improves efficiency and reduces labor cost. Automated milking parlours can keep track of each cow’s production data. This helps in making informed decisions.

However, the transition to automation is not without challenges. Farmers may face initial high costs. Training staff to operate new systems can be difficult. Moreover, reliance on technology can be daunting. What happens if the system fails? Backup plans are essential but often overlooked.

Despite potential issues, the benefits can outweigh the risks. Automation can significantly enhance milk quality. It allows for more consistent milking routines. Regular monitoring can lead to healthier cows. As technology evolves, so should our approach to dairy farming. Adaptability is key in this changing landscape.

Related Posts

-

Top 10 Essential Milking Parlour Equipment for Optimal Dairy Farm Efficiency

-

2025 Top Milking Equipment Innovations for Modern Dairy Farming

-

Essential Guide to Choosing Innovative Dairy Milking Equipment for Modern Farms

-

The Future of Dairy Farming How Cow Milking Equipment is Revolutionizing Milk Production

-

2025 How to Choose the Best Dairy Milking Equipment for Your Farm

-

How to Choose the Right Dairy Production Equipment for Your Farm Needs