How to Choose the Right Dairy Production Equipment for Your Farm Needs

Choosing the right dairy production equipment is essential for optimizing efficiency and enhancing productivity on modern dairy farms. According to the 2020 Global Dairy Industry Report, the global dairy equipment market is projected to reach $18.8 billion by 2025, driven by advancements in technology and increasing demand for dairy products. With the industry witnessing an average annual growth rate of approximately 5.5%, selecting suitable equipment has become a critical factor in maintaining competitive advantage.

In light of these developments, dairy farmers are faced with a myriad of equipment options designed to meet their unique operational needs. From milking systems to pasteurization units, the right dairy production equipment can significantly affect not just milk quality, but also labor costs and energy consumption. A study by the International Dairy Federation highlights that optimizing dairy equipment can reduce production costs by 10-20%, underscoring the importance of informed decision-making in equipment selection.

Ultimately, understanding the specific requirements of your dairy operation and staying informed about the latest technological innovations will empower you to make choices that promote sustainability and profitability in your farming practices. As the dairy sector continues to evolve, equipping your farm with the right dairy production equipment is not just an investment in machinery, but a strategic move towards future growth and success.

Understanding Your Dairy Farm's Specific Needs

When selecting the right dairy production equipment for your farm, understanding your specific needs is crucial. Different farms have varying production capacities, herd sizes, and milk processing requirements, so assessing these factors is essential. According to the USDA's National Agricultural Statistics Service, the average dairy farm in the United States milks approximately 150 cows, but this number can greatly vary. For smaller operations, equipment should focus on optimizing labor efficiency and maintaining milk quality, which may involve investing in automated milking systems or portable pasteurizers.

Moreover, it's important to consider facilities that can adapt to future growth. A report from the Agricultural and Applied Economics Association indicates that dairy farms are increasingly moving towards more integrated systems that allow for scalability. This integration often includes milking parlors, storage tanks, and blending equipment. Understanding your current production level and anticipating future needs can guide you in choosing multifunctional equipment that can evolve with your business, ensuring sustainability and profitability in an ever-changing market.

Key Types of Dairy Production Equipment to Consider

When selecting dairy production equipment for your farm, it's essential to consider the key types of equipment that align with your specific needs. Firstly, milking machines play a vital role in ensuring efficient and timely milk extraction. There are various models available, ranging from traditional bucket milking systems to modern automatic milking parlors that enhance productivity while maintaining milk quality. Consider the size of your herd and the frequency of milking to determine the best fit for your operation.

In addition to milking equipment, pasteurization units are crucial for ensuring the safety and quality of your dairy products. These units heat milk to eliminate harmful bacteria while preserving its nutritional value. Depending on your production scale, you may opt for batch or continuous pasteurizers. Other essential dairy equipment includes storage tanks, which are important for maintaining milk at optimal temperatures, and bottling or packaging machinery which streamlines your product distribution. Each piece of equipment should be chosen based on your farm’s size, production goals, and budgetary constraints to create a cohesive and efficient dairy operation.

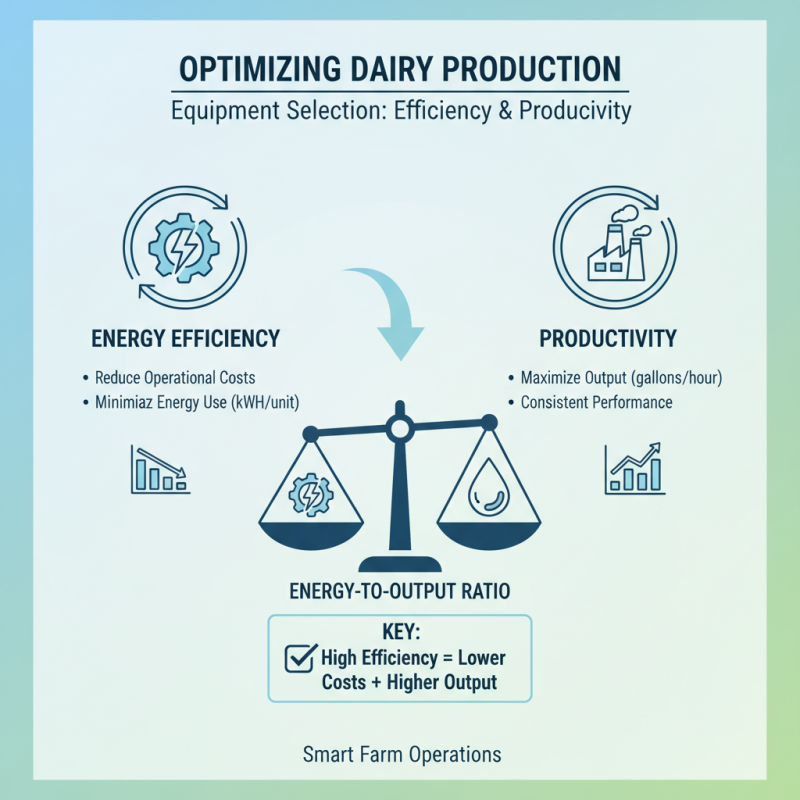

Evaluating Equipment Efficiency and Productivity Factors

When selecting dairy production equipment, evaluating its efficiency and productivity is essential for optimizing farm operations. One of the key factors to consider is the equipment's energy consumption. High-efficiency machines can significantly reduce operational costs by minimizing energy use without compromising output. Analyzing the energy-to-output ratio will allow farmers to determine which equipment maximizes productivity while keeping energy expenses in check.

Additionally, the maintenance needs of the equipment play a crucial role in overall productivity. Machines that require frequent repairs or have high maintenance costs can lead to unexpected downtimes, affecting milk production and, subsequently, profits. It's advisable to choose equipment designed for durability and ease of maintenance, ensuring that downtime is minimized, and the workflow remains uninterrupted.

**Tips:** Regularly assess your current equipment's efficiency by tracking performance metrics and maintenance records. Engaging with peers in the industry can provide insights into which machines offer the best productivity and long-term value. Testing machinery in real-world conditions, if possible, can also shed light on its efficiency before making a financial commitment.

Assessing Budget and Investment for Dairy Equipment

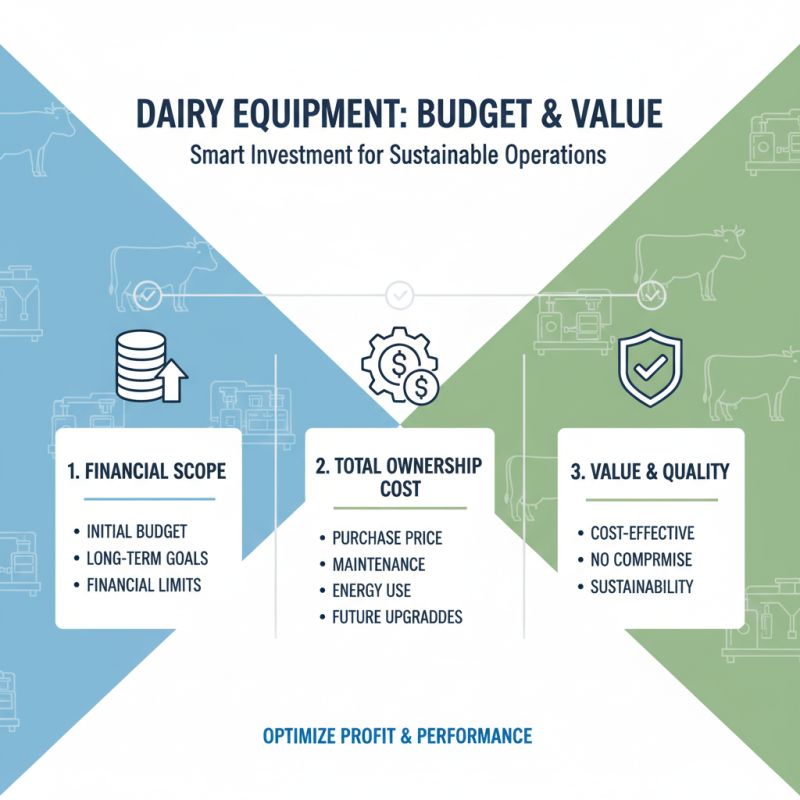

When selecting dairy production equipment, a well-thought-out budget is crucial. Begin by evaluating your financial constraints, as well as your long-term investment goals. Consider not only the initial purchase price of the equipment but also the total cost of ownership. This includes maintenance, energy consumption, and potential upgrade costs. Identifying the most cost-effective solutions that won’t compromise quality is essential for ensuring a sustainable dairy operation.

Additionally, it’s important to prioritize equipment based on your specific farm needs. Analyze your current production levels and future growth projections to determine which equipment will provide the best return on investment. Seeking financing options or assessing potential grants and subsidies can also help alleviate financial pressure. A clear understanding of both direct and hidden costs will empower you to make informed purchasing decisions, allowing your dairy business to thrive economically while meeting production targets.

Maintenance and Support for Optimal Dairy Equipment Longevity

When selecting dairy production equipment, maintenance and support play a crucial role in ensuring the longevity and efficiency of the machinery. According to a report by the USDA, proper maintenance can extend the lifespan of dairy equipment by up to 25%, significantly reducing replacement costs and downtime. Regular servicing, including inspections and part replacements, can prevent minor issues from escalating into major failures, safeguarding the productivity of dairy operations.

Moreover, investing in equipment with readily available technical support can make a substantial difference in operation efficiency. Research from the Dairy Research Institute indicates that farms leveraging comprehensive support services experience a 15% increase in productivity due to less time spent on equipment-related issues. Implementing a scheduled maintenance plan, coupled with real-time support, enables farmers to operate smoothly and respond quickly to unexpected challenges, ultimately enhancing the overall performance of their dairy production systems.

How to Choose the Right Dairy Production Equipment for Your Farm Needs - Maintenance and Support for Optimal Dairy Equipment Longevity

| Equipment Type | Purpose | Maintenance Frequency | Support Options | Expected Lifespan |

|---|---|---|---|---|

| Milking Machine | Milking cows efficiently | Daily | In-person and online support | 10-15 years |

| Pasteurizer | Treating milk to eliminate pathogens | Weekly | Maintenance contracts available | 15-20 years |

| Cooling Tank | Keeping milk at safe temperatures | Monthly | 24/7 assistance | 15-25 years |

| Feeding System | Automating cow feed distribution | Bi-weekly | Technical support hotline | 10-20 years |

| Manure Management System | Efficient disposal of waste | Monthly | Regular training sessions | 15-30 years |

Related Posts

-

How to Choose the Best Dairy Equipment for Your Farm in 2025

-

Top 10 Essential Milking Parlour Equipment for Optimal Dairy Farm Efficiency

-

10 Essential Tips for Choosing the Best Dairy Milk Products for You

-

Unlocking the Secrets of Dairy: How Milk Transforms Nutrition and Wellness

-

Top 10 Must-Try Dairy Milk Products for a Healthier Lifestyle

-

Exploring the Nutritional Benefits of Dairy-Infused Products You Didn't Know About