Top 10 Essential Milking Parlour Equipment for Optimal Dairy Farm Efficiency

In the fast-paced world of dairy farming, efficiency and productivity are paramount. Selecting the right milking parlour equipment is crucial for dairy operations to thrive and meet the demands of an ever-growing market. This essential equipment not only affects the speed and quality of the milking process but also plays a vital role in animal welfare and overall farm management.

As dairy farms face increasing pressures from consumer expectations and regulatory standards, investing in high-quality milking parlour equipment can lead to significant enhancements in farm efficiency. From advanced milking machines to automated cleaning systems, the right tools can streamline operations, reduce labor costs, and improve the consistency of milk quality. Ultimately, understanding the ten essential pieces of equipment for milking parlours will empower farmers to make informed decisions that will significantly impact their productivity and profitability in the competitive dairy industry.

Top 10 Essential Milking Parlour Equipment for Optimal Dairy Farm Efficiency

The efficiency of a dairy farm heavily depends on the quality and suitability of its milking parlour equipment. With the right tools, farmers can enhance their milk production process, ensuring both productivity and animal welfare. According to the Dairy Research Institute, farms that invest in modern milking parlour technology can see an increase in milk yield by up to 15%. Essential equipment includes automatic milking systems, which significantly reduce labor costs while improving milking speed and animal comfort.

One key tip for optimizing your milking parlour is to regularly maintain and calibrate your equipment. A study by the International Dairy Federation emphasizes that routine checks can decrease downtime by 20%, allowing for a more consistent milking schedule. Additionally, utilizing advanced monitoring systems can provide real-time data on milk quality and animal health, enabling prompt adjustments and interventions.

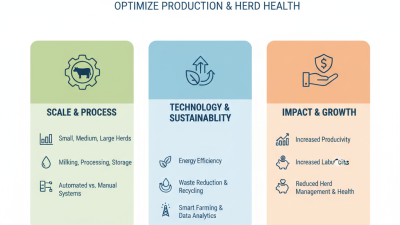

To further enhance efficiency, consider integrating herd management software with your milking systems. This technology can streamline your operations by tracking individual cow performance and automating feeding schedules based on milking times. According to the Journal of Dairy Science, leveraging data analytics can lead to a 10% reduction in feed costs over time, directly impacting your farm's bottom line. In summary, investing in the right milking parlour equipment and leveraging technology not only optimizes operations but also promotes sustainable farming practices.

Importance of Milking Parlour Design for Dairy Production Efficiency

The design of a milking parlour plays a crucial role in enhancing the efficiency of dairy production. A well-thought-out layout facilitates smoother workflow, reducing the time required for milking and allowing farm staff to focus on other critical tasks. Key factors such as the flow of cows, accessibility for workers, and the positioning of equipment significantly impact operational efficiency. For instance, minimizing the distance cows must walk to enter and exit the parlour can lead to less stress for the animals and quicker milking times, ultimately improving overall productivity.

Moreover, the integration of modern technology within milking parlour design can optimize milk quality and output. Automated systems for milking, cleaning, and monitoring health can create a more streamlined process that not only enhances efficiency but also ensures better animal care. Furthermore, incorporating ergonomic considerations for workers can reduce strain and injury, leading to a more committed workforce. Ultimately, a strategically designed milking parlour contributes to higher milk yields, better cow health, and a more sustainable dairy operation, solidifying its importance in the overall production strategy of a dairy farm.

Top 10 Essential Milking Parlour Equipment for Optimal Dairy Farm Efficiency

Key Features of Automated Milking Systems in Modern Dairy Farming

Automated milking systems (AMS) are revolutionizing the dairy industry by enhancing efficiency and animal welfare on modern farms. According to a report by the International Dairy Federation, the introduction of AMS has resulted in a 20-30% increase in milk production per cow while significantly reducing labor costs. These systems enable farmers to milk their cows more frequently and at their convenience, leading to improved milk quality and higher yields. The flexibility provided by AMS allows for better management of the herd, allowing for individualized milking schedules that cater to the needs of each cow.

Key features of these automated systems include cow identification, precise milk measurement, and health monitoring capabilities. Advanced AMS technologies utilize sensors and cameras to gather data about milk yield, quality, and cow health, alerting farmers to any potential issues, such as mastitis, long before they become serious. A study published in the Journal of Dairy Science indicates that farms employing AMS exhibit a marked decrease in veterinary costs due to proactive health management. This data underscores how automation not only streamlines milking operations but also fosters a healthier herd, yielding long-term benefits for dairy producers.

Milking Machines: Types, Efficiency Ratings, and Usage Data

Milking machines are a crucial component of modern dairy farming, significantly influencing the efficiency and productivity of milk production. There are several types of milking machines, including conventional bucket systems, pipeline systems, and rotary parlors, each tailored to various herd sizes and farming practices. According to the Dairy Farmers of America, automated milking systems can reduce labor costs by up to 30%, while increasing milking efficiency by 20%. These machines are equipped with advanced technology that enables real-time monitoring of milk yield and udder health, ultimately leading to improved herd management.

When selecting milking equipment, efficiency ratings play a vital role in ensuring optimal performance. The efficiency of a milking machine can be gauged through metrics such as the average milking time per cow, milk recovery times, and energy consumption. A report by Rabobank highlights that effective milking machines can save farmers upwards of 15 minutes per session compared to traditional milking methods. Additionally, understanding your herd's behaviors and milking patterns is essential, as this data can inform how to best utilize the equipment for maximum throughput.

Tip: Regular maintenance of your milking machine is essential for maintaining its efficiency. Schedule routine checks to ensure that all components are functioning correctly and that any worn parts are replaced promptly.

Tip: Consider investing in milking machines that offer data analytics capabilities. This feature enables farmers to gain insights into milking trends, which can lead to more informed decisions about herd management and overall farm efficiency.

Role of Milk Cooling and Storage Equipment in Quality Preservation

The quality of milk produced on a dairy farm is heavily influenced by the effectiveness of cooling and storage equipment. Once the milk has been collected, it is crucial to cool it down quickly to inhibit bacterial growth and preserve its freshness. This is where milk cooling tanks come into play. These tanks lower the milk temperature rapidly, typically to around 4°C, ensuring that the milk maintains its quality from the moment it is harvested until it reaches processing facilities. The installation of efficient cooling systems can significantly reduce spoilage and enhance the overall shelf life of the product, making it essential for any dairy operation.

Moreover, proper storage practices complement cooling efforts to safeguard milk quality. Storage silos or tanks equipped with temperature control features help in maintaining optimal conditions for milk. Regular monitoring of storage environments is vital to ensure that milk remains free from contamination and chemical changes. Additionally, effective storage solutions facilitate better inventory management, allowing for precise tracking of milk quality and freshness, which is crucial for meeting industry standards and consumer expectations. Thus, investing in high-quality milk cooling and storage equipment is not only fundamental for preserving milk quality but also for enhancing the operational efficiency of a dairy farm.

Conclusion

The article "Top 10 Essential Milking Parlour Equipment for Optimal Dairy Farm Efficiency" emphasizes the critical role of milking parlour equipment in enhancing dairy farm productivity and efficiency. It discusses the importance of a well-designed milking parlour that maximizes workflow and minimizes stress for both the animals and the operators. Key features of automated milking systems are highlighted, showcasing their ability to streamline operations and improve milk yield.

Additionally, the article delves into various types of milking machines, their efficiency ratings, and operational data, providing insights on their usage in modern dairy farming. The significance of milk cooling and storage equipment for maintaining quality is also examined, along with advanced cleaning and sanitization tools that ensure hygiene in the parlour. Overall, the right milking parlour equipment is essential for optimizing dairy production processes, ensuring both high-quality output and effective management.

Related Posts

-

2025 Top Milking Equipment Innovations for Modern Dairy Farming

-

Essential Guide to Choosing Innovative Dairy Milking Equipment for Modern Farms

-

The Future of Dairy Farming How Cow Milking Equipment is Revolutionizing Milk Production

-

2025 How to Choose the Best Dairy Milking Equipment for Your Farm

-

2025 How to Choose the Best Dairy Equipment for Your Farm Production

-

Exploring the Health Benefits of Consuming Diverse Milk Products in Your Daily Diet