Top Dairy Barn Equipment for 2026 What to Consider?

In the evolving landscape of the dairy industry, choosing the right dairy barn equipment is crucial for success. Industry expert Dr. Jane Thompson once stated, "Investing in quality equipment can transform your dairy operations." As we approach 2026, considerations for selecting efficient and durable equipment are more important than ever.

When evaluating options, think about functionality. Prioritize gear that enhances milk production while ensuring the animals' comfort. It's essential to assess how technology can streamline operations. Automation and smart technology present both opportunities and challenges.

Reflect on past purchases to avoid repeating mistakes. What worked and what didn't? Are there features that were overrated? These reflections can guide better decision-making moving forward. Ultimately, your choices in dairy barn equipment will significantly influence your farm’s productivity and animal welfare.

Key Factors in Choosing Dairy Barn Equipment for 2026

When selecting dairy barn equipment for 2026, there are several key factors to consider. Efficiency is crucial. Reports indicate that around 30% of operational costs in dairy farming stem from outdated equipment. Upgrading to modern systems can significantly reduce expenses and enhance productivity. Automatic milking systems are popular choices, as they can boost milk yield by up to 15% annually.

Animal welfare also plays a vital role. Well-designed barns improve cow comfort. Research shows that cows in comfortable environments produce more milk. Equipment should ensure proper ventilation and adequate space. This helps to prevent stress, which can lead to a decline in productivity.

Sustainability has become increasingly important. Farmers now focus on eco-friendly solutions. In fact, investments in renewable energy within dairy operations have seen a growth of 25%. Choosing equipment that minimizes waste and conserves resources is essential. Reflecting on these factors can guide better decisions for the future of dairy farming. Recognizing the balance between cost, efficiency, and sustainability can be challenging, yet it's necessary for success in the coming years.

Top Dairy Barn Equipment for 2026 - Key Factors in Choosing Dairy Barn Equipment

| Equipment Type | Key Features | Considerations | Estimated Cost ($) | Maintenance Level |

|---|---|---|---|---|

| Milking Machines | High efficiency, multi-cow operation, ease of use | Compatibility with existing systems, training requirements | 15,000 - 30,000 | Medium |

| Feed Mixing Equipment | Precision mixing, various configurations, automation | Feed type compatibility, space requirements | 20,000 - 50,000 | High |

| Manure Management Systems | Efficient waste removal, odor control, environmental compliance | Location, environmental regulations | 10,000 - 25,000 | Medium |

| Barn Ventilation Systems | Airflow optimization, temperature control, energy efficiency | Size of barn, climate considerations | 5,000 - 15,000 | Low |

| Robotic Feeders | Automated feeding, labor-saving, precision delivery | Initial investment, integration with existing systems | 30,000 - 70,000 | High |

Essential Dairy Barn Equipment Types for Optimal Operations

In 2026, dairy farms will need essential equipment for optimal operations. One critical category is milking systems. According to a recent industry report, automated milking systems can increase efficiency by up to 30%. This technology allows farmers to milk cows without manual labor. However, the initial costs can be high, and not all farms will see immediate returns.

Another important aspect is feed management equipment. A study revealed that effective feeding can boost milk production by 15%. Feed mixers and grain bins help ensure balanced nutrition. These systems require regular maintenance, which can be a challenge for some operations. Balancing efficiency and upkeep is crucial.

Manure management tools are also vital. They prevent environmental issues and enhance farm sustainability. For instance, anaerobic digesters can convert waste into energy. However, this equipment requires technical expertise and can be complex to manage. Adopting new technology demands careful planning and consideration. Farmers must assess their unique needs before investing in these systems.

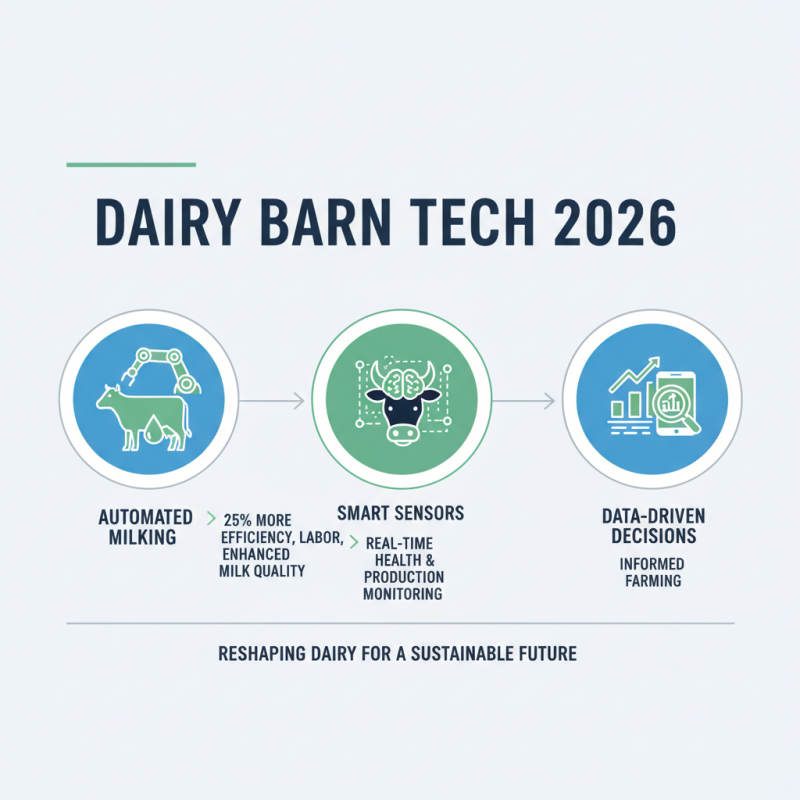

Innovative Technologies in Dairy Barn Equipment for 2026

Innovative technologies are reshaping dairy barn equipment in 2026. Automated milking systems are becoming a standard. These systems can increase milking efficiency by 25%. They reduce labor costs and enhance milk quality. Sensors monitor cow health and milk production in real-time. This data helps farmers make informed decisions.

Robotic feeding systems are also gaining popularity. These machines can deliver feed with precision. Reports show that they can reduce feed waste by up to 15%. This efficiency leads to cost savings and better nutrition for the herd. Smart barn management software integrates various technologies. It allows farmers to track and analyze herd performance seamlessly.

However, challenges remain. High upfront costs can be a barrier for many farms. Training staff to operate new machinery can be daunting. Compatibility between old and new systems may lead to technical issues. It is essential to find a balance between innovation and practicality. The dairy industry must embrace these advancements while addressing potential obstacles.

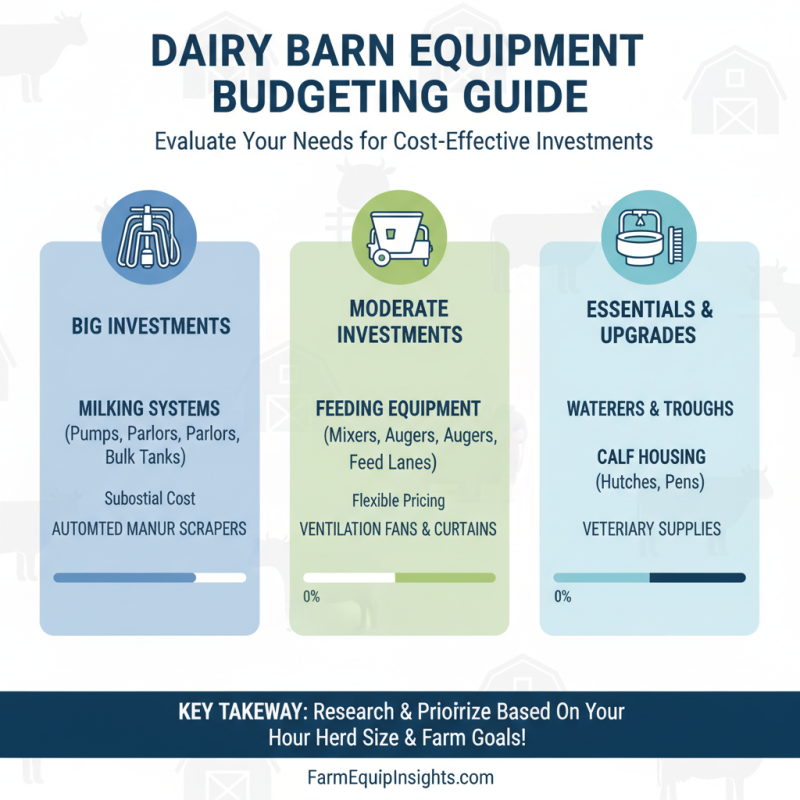

Cost Considerations and Budgeting for Dairy Barn Equipment

When budgeting for dairy barn equipment, costs can vary widely. It’s important to evaluate your specific needs. Some items, like milking systems, can be substantial investments. Others, such as feeding equipment, might offer more flexibility in pricing.

Consider how equipment affects overall productivity. A higher upfront cost can lead to long-term savings. However, you must ensure it fits within your operational budget. Unexpected expenses can arise, such as maintenance or upgrades. Keeping these in mind is crucial.

You should also factor in financing options. Leasing equipment could ease cash flow issues. But this may not work for everyone. Assessing the return on investment is necessary. Reevaluate choices regularly. Flexibility in budgeting allows room for adjustments as your farm evolves.

Maintenance and Sustainability in Dairy Barn Equipment Selection

Selecting dairy barn equipment for sustainability requires careful consideration. Maintenance practices play a vital role in long-term efficiency. According to the USDA, proper equipment upkeep can reduce energy costs by 25%. Ensuring that machinery operates at peak performance minimizes waste and conserves resources.

When purchasing equipment, think about durability. Many components need frequent repairs. A 2021 report indicates that nearly 40% of dairy farms experience equipment failures that lead to unplanned downtime. This not only impacts milk production but also costs money. Choosing equipment designed for longevity can help mitigate these issues.

Another factor is energy usage. The dairy sector accounted for 18% of total agricultural greenhouse gas emissions in 2020. Selecting energy-efficient machines can significantly lower this footprint. Moreover, the shift towards renewable energy sources in farming is gaining traction. Yet, half of the dairy farm managers express concerns about the initial costs of sustainable equipment. Balancing investment with environmental impact is essential, and ongoing maintenance should never be overlooked.

Top Dairy Barn Equipment for 2026

This chart represents the projected investment amounts in various dairy barn equipment for 2026. It highlights the focus areas for maintenance and sustainability within the dairy industry. As technology advances, these areas will play a crucial role in optimizing dairy farm operations.

Related Posts

-

Essential Dairy Barn Equipment Upgrades for Modern Farming Efficiency

-

2026 Top Milking Parlour Equipment for Efficient Dairy Farming?

-

Essential Guide to Choosing Innovative Dairy Milking Equipment for Modern Farms

-

Top 10 Milking Parlour Equipment Every Dairy Farmer Needs?

-

How to Choose the Best Dairy Products and Milk for Your Health in 2025

-

Why Are Dairy Milk Products Essential for Your Health and Nutrition