Top 10 Dairy Production Equipment You Need for Success?

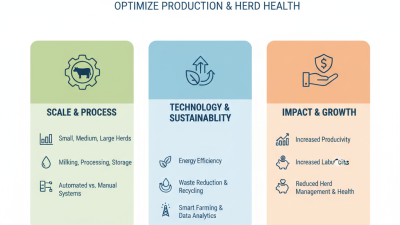

In today’s competitive dairy market, investing in the right dairy production equipment is crucial for growth and efficiency. Industry experts emphasize its importance. Dr. Emily Carter, a leading dairy technology specialist, states, “Effective dairy production equipment can significantly boost productivity and quality.” According to a recent report by DairyTech Insights, the global dairy equipment market is projected to reach $20 billion by 2025. This figure underscores the significant investment many dairy farms are making in modern technology.

Selecting the top equipment is not just about purchasing the latest models. It involves understanding specific needs and local conditions. The right equipment can streamline processes, ensuring milk quality and safety. However, many producers still struggle with outdated technology. Some farms face challenges in maintenance and adaptability. It’s important to learn from these experiences.

Emerging equipment trends highlight automation and energy efficiency. Producers must assess how these advancements fit their operations. There’s a learning curve, and initial costs can be daunting. Yet, adaptable equipment often pays off in the long run. Finding the balance between investment and return on efficiency remains a challenge for many. Proper planning and guidance are essential for successful implementation.

Essential Dairy Production Equipment for Optimal Efficiency

In the dairy production industry, efficiency is critical. According to a report by the Dairy Equipment Manufacturers Association, efficient equipment can improve productivity by up to 30%. Essential dairy production equipment includes pasteurizers, separators, and filling machines. Each piece plays a vital role in maintaining quality and safety standards. However, challenges can arise in selecting the right equipment that suits specific needs.

For example, many dairy farms still rely on outdated technologies. These can lead to increased energy costs and lower output. The USDA emphasizes that modernizing equipment can result in significant savings. While newer technologies require an upfront investment, they often pay off in reduced operational expenses over time.

Additionally, proper maintenance is crucial for efficiency. Neglecting routine checks can lead to breakdowns and production halts. Some farms might overlook this aspect, thinking it saves money. In reality, this short-term thinking can harm long-term profitability. Efficiency in dairy production is a complex balance of choosing the right equipment and ensuring it runs smoothly.

Understanding the Role of Milking Machines in Dairy Operations

Milking machines are essential in modern dairy operations. These machines automate the milking process, which improves efficiency. According to industry reports, utilizing milking equipment can increase milk yield by up to 15%. This boost enables dairy farmers to maximize profits while maintaining animal welfare.

Choosing the right milking system is crucial. A well-functioning machine minimizes stress on cows. In addition, improperly maintained equipment can lead to lower milk quality. Regularly inspecting your machines ensures optimal performance. Battery-powered units have various advantages, especially in remote areas. However, these may require frequent charging and maintenance.

Tip: Invest in training for your staff on machine usage. Knowledgeable operators extend equipment life. Consider the size of your dairy herd when selecting milking equipment. A system that fits your operation reduces risks and enhances productivity. Remember, not every system is perfect for your needs. It's essential to learn from mistakes to improve efficiency.

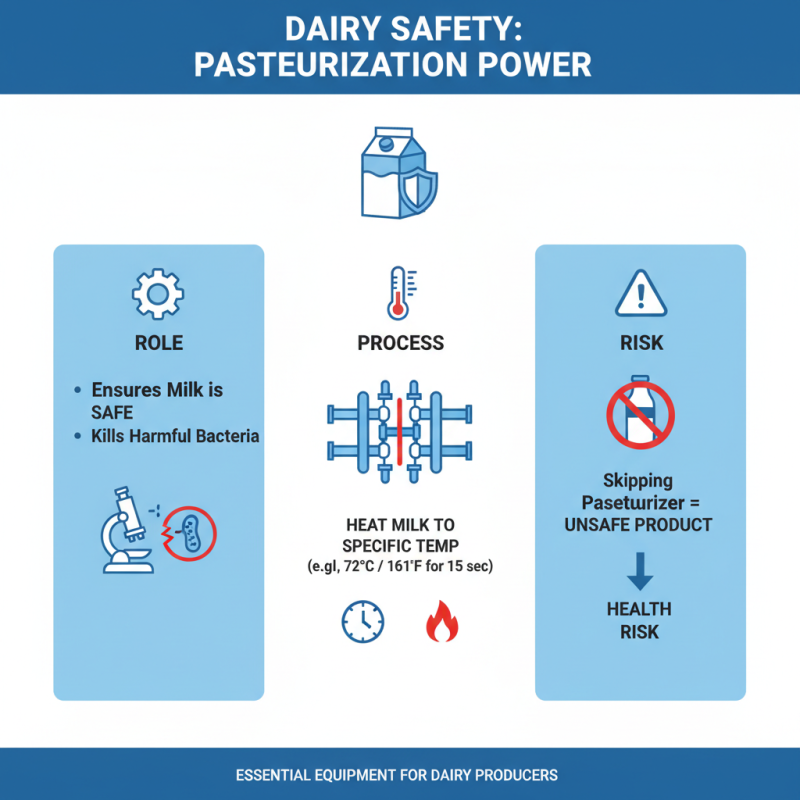

Importance of Pasteurizers in Ensuring Milk Safety and Quality

Pasteurizers play a critical role in the dairy industry. They ensure that milk is safe for consumption. The process of pasteurization involves heating milk to a specific temperature. This step kills harmful bacteria. Yet, some producers overlook this essential equipment. They may focus on other tools instead, risking product safety.

Inadequate pasteurization leads to serious consequences. Consumers could face health risks. Additionally, the quality of milk may drop. It's vital for dairy businesses to prioritize this equipment. Regular maintenance is also necessary. Many ignore this aspect, leading to inefficiencies. Investing in reliable pasteurizers enhances product quality. It builds consumer trust.

Some may think pasteurizers are too costly. This mindset can hinder success. Skipping on this may save money short-term, but it could harm the brand long-term. Reflecting on these decisions is crucial for growth. Quality assurance should never be compromised in the dairy sector.

Key Storage Solutions for Maintaining Dairy Product Freshness

Maintaining the freshness of dairy products is crucial. Proper storage solutions can significantly impact product quality. To avoid spoilage, temperature control is essential. Dairy products should ideally be stored at temperatures below 4°C. Any fluctuation can lead to significant quality loss.

Using airtight containers helps in preserving flavor. Glass or food-safe plastic are good choices. They prevent contamination from other foods. Proper labeling is important too. It helps track expiration dates more effectively. Many overlook this step, leading to waste.

Regular temperature checks are critical. Invest in reliable thermometers to monitor your storage units. Many dairies fail to maintain consistent conditions. It's worth assessing existing practices and making necessary adjustments. Sometimes, what seems adequate may not be enough for optimum freshness.

Top 10 Dairy Production Equipment You Need for Success

This chart illustrates the importance of various dairy production equipment in maintaining the freshness of dairy products. The data reflects the average effectiveness rating of each equipment type based on industry surveys.

Investing in Automated Feeding Systems for Dairy Herd Management

Investing in automated feeding systems can transform dairy herd management. These systems deliver precise amounts of feed at the right time. This reduces waste and ensures that cows receive optimal nutrition. Consistency in feeding helps improve milk yield. Daily routines become less labor-intensive with automation in place.

However, the initial investment can be daunting. Not every farm sees the same benefits from these systems. It’s essential to assess your herd size and management practices. Some farmers might struggle with maintenance and technical issues. Training staff to operate these systems is equally important. If not done correctly, inefficiencies can arise.

Automation also allows for real-time monitoring of cow health. Farmers receive immediate feedback on feeding patterns and behaviors. This information can lead to quicker decision-making. Yet, reliance on technology can sometimes overlook the human aspect of care. Balancing automation with personal attention to animals is key for long-term success.

Top 10 Dairy Production Equipment You Need for Success

| Equipment | Purpose | Benefits |

|---|---|---|

| Automated Milking Systems | Milking cows without manual intervention | Increases efficiency and reduces labor costs |

| Feed Management Systems | Automates feeding schedules and rations | Improves feed efficiency and animal health |

| Milk Cooling Tanks | Rapid cooling of milk post-milking | Maintains milk quality and extends shelf life |

| Breeding Management Software | Tracks breeding cycles and health | Enhances reproduction rates and herd genetics |

| Manure Management Systems | Handles livestock waste effectively | Improves farm hygiene and crop yields |

| Cooling and Ventilation Units | Regulates barn temperature and air quality | Enhances cow comfort and milk production |

| Health Monitoring Devices | Monitors cow vitals and alerts for health issues | Early detection of illnesses, reducing veterinarian costs |

| Water Management Systems | Automates water supply and quality checks | Enhanced hydration and overall cattle health |

| Robotic Cleaners | Automates barn cleaning processes | Saves labor time and improves barn conditions |

| Data Analytics Tools | Analyzes production data for better decision-making | Optimizes production and boosts profitability |

Related Posts

-

2025 How to Choose the Best Dairy Equipment for Your Farm Production

-

2025 How to Choose the Best Dairy Milking Equipment for Your Farm

-

How to Choose the Right Dairy Production Equipment for Your Farm Needs

-

Top 10 Best Dairy Industry Equipment for Efficient Production Systems?

-

How to Choose the Right Milking Parlour Equipment for Your Dairy Farm?

-

What is Milking Equipment Manufacturers and Their Role in Dairy Industry?