2026 Top Milking Parlour Equipment for Efficient Dairy Farming?

Dairy farming is evolving quickly, and efficient milking parlour equipment plays a crucial role. According to recent reports, the global dairy equipment market is expected to reach $22 billion by 2025. This growth reflects the increasing demand for high-quality milk and better efficiency in dairy operations.

Advancements in technology are reshaping how farmers approach milking. Automated systems can reduce labor costs while improving milking efficiency. However, not every farm can afford the latest innovations. Balancing cost and effectiveness remains a challenge for many producers. Some equipment may require significant investment but could lead to long-term savings.

In 2026, the best milking parlour equipment should enhance productivity and animal welfare. The key is finding solutions that fit each farm's unique needs. Consideration of real-world challenges is essential. Innovations are exciting but should not overlook practical applications. It’s about combining technology with traditional farming wisdom for better outcomes.

2026 Milking Parlour Trends: Innovations in Automated Systems

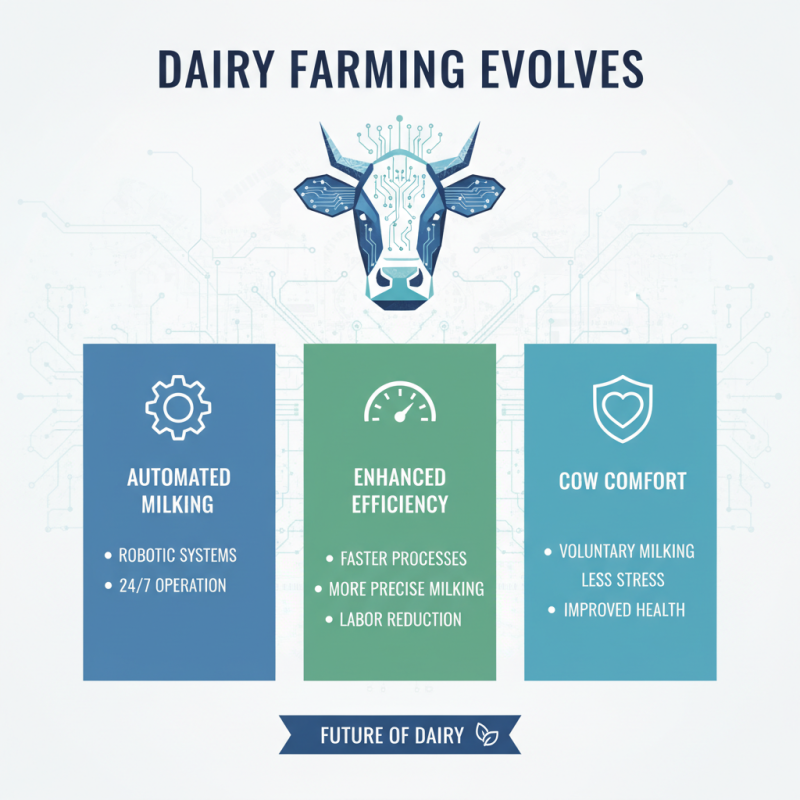

The dairy farming industry is evolving rapidly. Automated milking parlours are at the forefront of this change. These systems enhance efficiency and improve cow comfort. Innovations are making milking processes faster and more precise.

With wireless technology, farmers can monitor herds remotely. Data collection helps in tracking milk production patterns. This can lead to better management decisions. However, the reliance on tech may sometimes lead to data overload. Farmers must learn to interpret and utilize this information effectively.

Robotics in milking parlours also reduces labor costs. Machines can operate consistently, providing a steady output. Yet, the initial investment can be significant. Not all farms can afford such upgrades. It raises questions about accessibility and equity in dairy farming. The balance between automation and traditional methods remains an ongoing debate.

Key Performance Indicators for Efficient Dairy Farming in 2026

Efficient dairy farming in 2026 requires a focus on key performance indicators (KPIs). Research shows that maintaining a minimum of 2.5% milk quality through proper sanitation is essential. A survey indicates that 68% of dairy farmers track milk yield per cow. This metric is vital for assessing herd productivity.

Another crucial KPI is feed conversion ratio (FCR). Studies suggest that an FCR below 1.5:1 minimizes waste and maximizes output. However, many farms struggle to achieve this. Inadequate nutrition planning often leads to inefficiencies. Additionally, monitoring reproductive performance can reveal significant insights. Achieving a pregnancy rate of over 30% can drastically improve operational viability.

Farmers must not only focus on data but also reflect on their practices. Are they using technology effectively? Too many still rely on outdated methods. Rethinking processes could uncover hidden gains. Integrating advanced sensors can streamline operations. Yet, many hesitate due to costs. Balancing initial investments with long-term benefits is a challenging yet necessary conversation.

Impact of Milking Parlour Design on Herd Health and Milk Yield

The design of milking parlours plays a crucial role in herd health and milk yield. Studies indicate that well-designed parlours contribute to higher production levels and healthier cows. A report from the Dairy Research Institute shows that proper layout can improve cow flow, reducing stress during milking. Stress directly affects milk production, potentially decreasing yield by up to 15%.

Tips: Consider the cow's perspective when designing your parlour. Make sure exit and entrance points are clear.

Space is another critical factor. Cows need enough room to move comfortably. Overcrowded parlours can lead to injuries and lower milk output. A survey from Farm Management Association found that farms with spacious designs reported 10% higher average milk yields.

Tips: Regularly assess your parlour layout. Look for areas that may need more room or better access.

Innovative technology also impacts efficiency. Automated systems can ensure better milking conditions. However, not all farms are equipped for such changes. It’s essential to evaluate your current infrastructure before investing. Strive for balance between technology and traditional methods.

Sustainability Practices in Milking Equipment for Eco-Friendly Dairy

The push for sustainability in dairy farming is gaining momentum. Farmers are seeking eco-friendly solutions in milking parlour equipment. Energy-efficient machinery can play a crucial role. Technologies that utilize less water and energy are favored. This not only reduces costs but also lessens environmental impact.

A key focus is on materials. Recyclable and sustainable components are becoming standard. However, many farms still rely on outdated equipment. Upgrading can be costly, and not every farmer sees immediate benefits. Yet, investing in modern systems could improve efficiency over time.

Some farmers might hesitate. The pressure to adopt new practices can be overwhelming. Balancing tradition and innovation remains a challenge. It requires careful planning and commitment. Adaptation is essential for eco-friendly farming, and it starts with the right equipment.

Cost-Benefit Analysis of Advanced Milking Machinery Investments

Investing in advanced milking machinery can greatly enhance dairy farm efficiency. A recent industry report indicates that farms using automated milking systems can increase milking efficiency by up to 30%. This significant boost in productivity often translates into better milk yield per cow. However, the initial investment can be substantial, often exceeding $200,000 for a complete system.

The cost-benefit analysis reveals complexities. While labor savings are clear, farmers must also consider maintenance costs. Studies show that over a five-year period, maintenance can eat into profits. Unexpected breakdowns can disrupt the milking schedule, affecting overall dairy output. Additionally, farmers need to train staff on new technologies, which may lead to initial inefficiencies.

Not all farms benefit equally from advanced equipment. For smaller operations, the return on investment might take longer to realize. A detailed financial analysis tailored to each farm is crucial. Some producers report mixed results, highlighting the importance of evaluating specific needs before making a move. Adopting new technology isn't just about cutting costs; it requires careful planning and a willingness to adapt to new processes.

Related Posts

-

Essential Dairy Barn Equipment Upgrades for Modern Farming Efficiency

-

Why Buy Dairy Products Online? The Benefits You Can't Ignore

-

Top 10 Essential Milking Parlour Equipment for Optimal Dairy Farm Efficiency

-

How to Choose Healthy Dairy Products for Your Diet

-

What is the Role of Dairy Equipment Suppliers in Modern Dairy Farming

-

10 Essential Tips for Buying Dairy Products Online Safely and Freshly